ABOUT CHI HSING

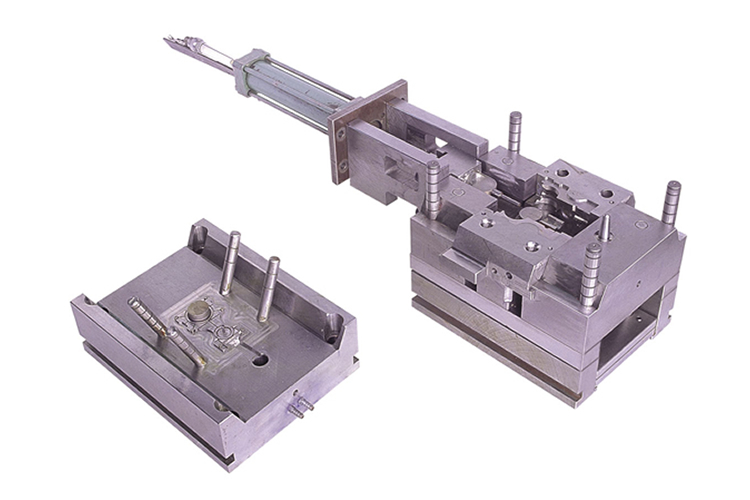

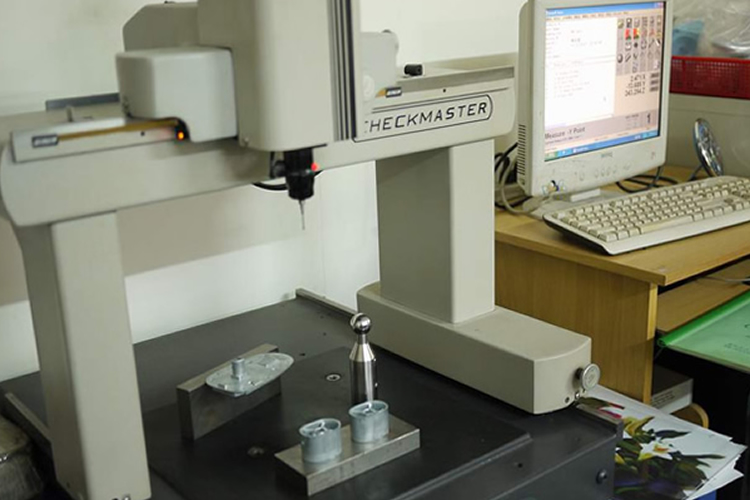

Founded in 1978, we are professional manufacturer of zinc alloy products, and hardware products with other material.Our line of die-casting machines includes 60-ton to powerful 500-ton models, so we can fill your orders for heavy parts (up to 10 kgs) as well as lightweight hardware (0.01kg).

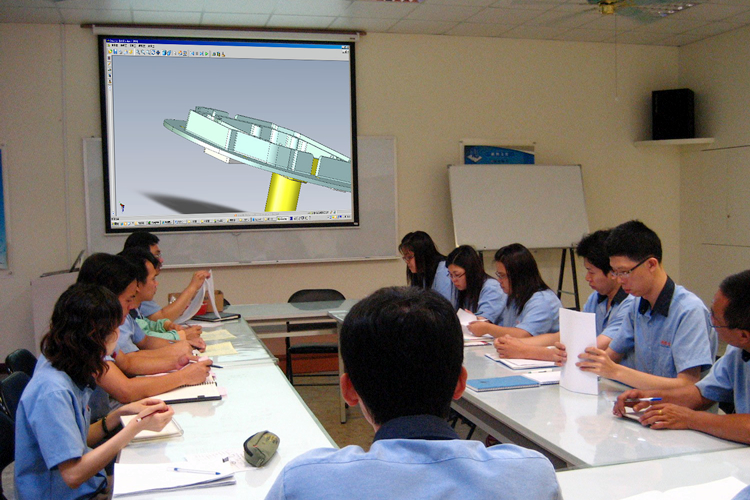

We offer the whole producing processes for finish goods which means one stop service. We also have factories both in Taiwan and Mainland China. Our professional experience and reliable attitude can help you be more competitive in today’s global market.

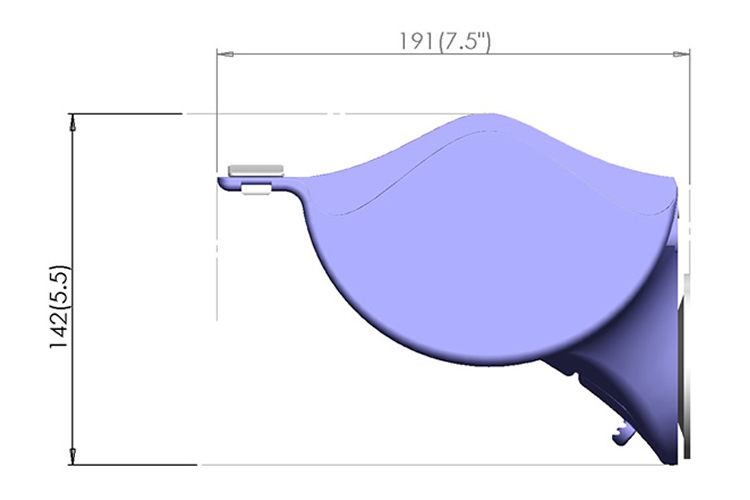

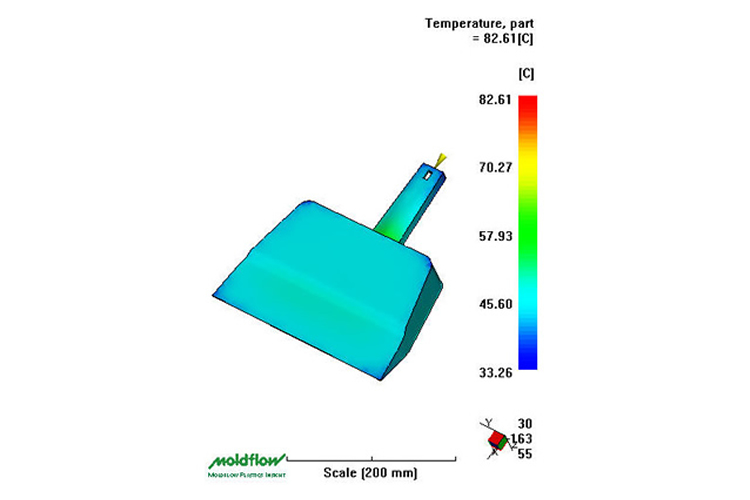

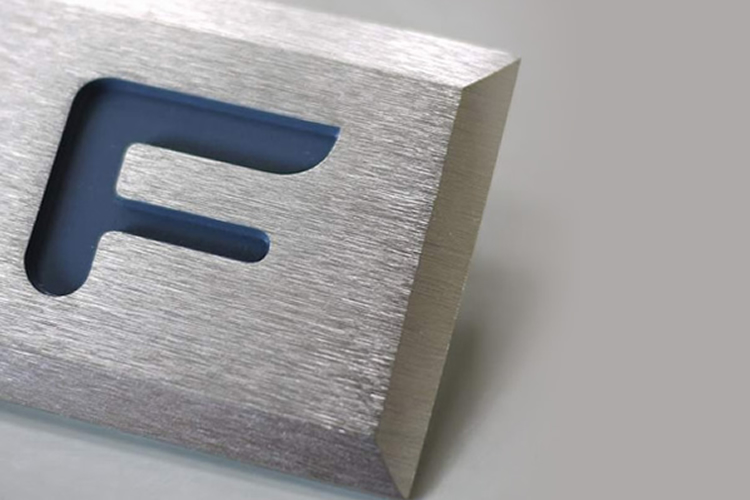

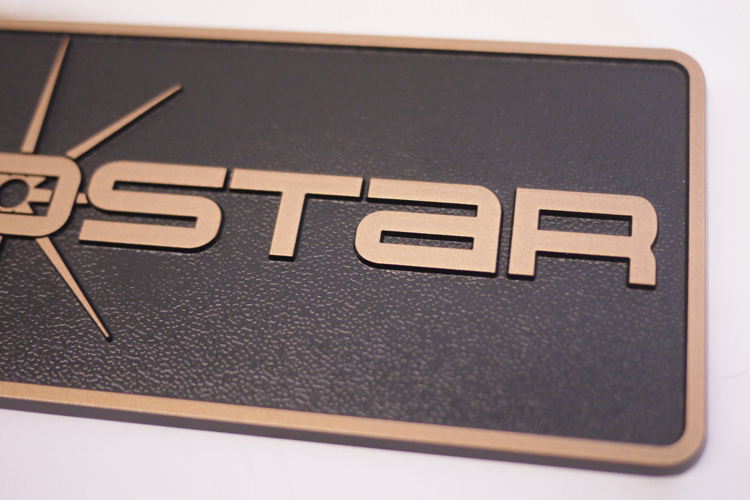

Professional OEM Zinc Die-casting Products :

OEM Service、Structure Modification、New Product Development、Working Process Improvement、Structure Design、Hardware Purchasing Workshop movie